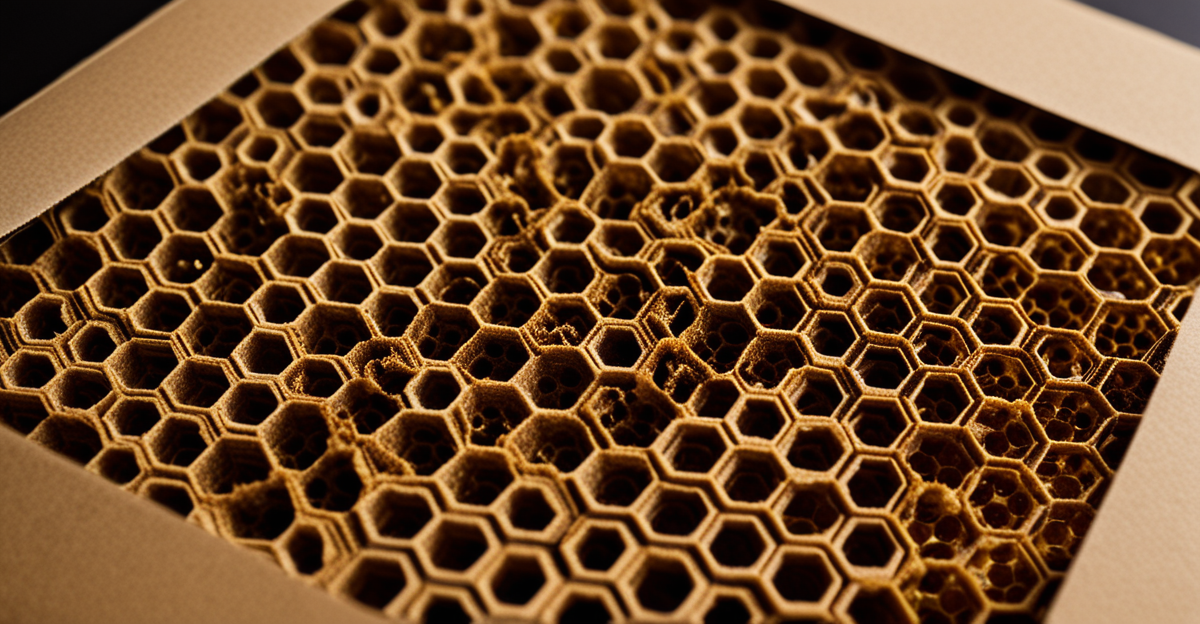

Honeycomb cardboard combines exceptional strength with remarkable lightness, making it perfect for durable yet eco-friendly signage and packaging solutions. Its recycled pulp core offers sustainability without compromising structural integrity. Versatile and customizable, this material adapts to diverse applications—from retail displays to furniture—while supporting environmentally conscious choices in design and manufacturing.

Comprehensive Overview and Immediate Uses of Honeycomb Cardboard

Honeycomb cardboard is an innovative material engineered for strength, sustainability, and lightweight performance. As highlighted on the page Estic maillot, its core comprises a hexagonal grid structure sandwiched between two paper liners—most often crafted from recycled or virgin Kraft papers. This design delivers remarkable vertical compression resistance while using minimal resources, making it particularly adept at distributing loads and absorbing impacts in packaging and display applications.

Additional reading : How to Create a Robust Digital Transformation Strategy for UK Healthcare Providers?

The essential material properties of honeycomb cardboard include its exceptional strength-to-weight ratio, allowing it to withstand compressive forces well beyond conventional corrugated boards. The honeycomb core’s geometry offers superior rigidity and stability. This means honeycomb cardboard sheets can be manufactured in a variety of thicknesses, ranging from a slim 1 mm ideal for craft and creative modeling, up to robust 50 mm panels used for heavy-duty shipping or industrial void fill.

Immediate applications span a wide scope:

Additional reading : What Are the Key Trends in the UK Renewable Energy Sector for 2023?

- Packaging solutions for fragile goods (such as electronics or glass), where shock absorption and durability are vital.

- Signage and POS displays benefit from the lightweight panels that remain rigid and endure repeated handling.

- Crafting and art projects utilize the material’s ability to be easily cut, printed, or shaped.

- Furniture and interior design industries increasingly rely on honeycomb core cardboard for eco-conscious concepts that are sturdy yet easy to move.

Key benefits of honeycomb cardboard are both practical and sustainable. It is:

- Lightweight, reducing shipping and material handling costs

- Highly recyclable and made from recycled content, supporting eco-friendly packaging initiatives

- Cost-effective, especially when compared with traditional wooden crates or plastic-based materials

- Customizable in thickness and size for tailored uses—from small pads and blocks to large sheets or panels.

From logistics and creative displays to furniture and reusable industrial packaging, honeycomb cardboard continues to gain traction thanks to its blend of strength, sustainability, and versatility.

Structural Design, Thickness Options, and Strength Features

Honeycomb core panels achieve strength through a unique structure where a series of hexagonal cells uniformly disperse weight. This cellular design, integral to honeycomb cardboard, channels the applied force across the entire panel, drastically improving overall load distribution. For packaging and furniture, this translates into panels that can handle significant vertical compression while remaining much lighter than solid alternatives.

Multiple honeycomb cardboard sheet sizes and thickness options exist to serve different uses. Standard dimensions, such as 2m x 1.2m sheets, streamline production, while custom sizes and grades adapt to individualized requirements. A comprehensive honeycomb cardboard sheet thickness guide covers applications from 8mm (used for cushioning) up to 50mm (designed for heavy-duty shipping or palette protection). Choosing the right sheet thickness enables optimal performance in everything from industrial packaging to home furniture builds.

Strength testing is essential before implementation. Honeycomb cardboard box strength tests measure crush resistance, edge protection, and stacking abilities, all of which validate durability under transport or storage stress. By relying on repeatable, measured results, users ensure that their honeycomb core panels for furniture or packaging can withstand regular, demanding use. This makes honeycomb cardboard especially reliable for eco-friendly, robust, and cost-efficient solutions.

Versatile Applications and Custom Engineering Solutions

Honeycomb cardboard is renowned for its ability to address a spectrum of practical requirements. In eco packaging solutions, it excels due to its lightweight and robust honeycomb core, offering significant protection for goods during transit. Manufacturers leverage the honeycomb cardboard sheet manufacturing process to produce panels of varying thickness, from 8mm up to 50mm, catering to uses such as dunnage, signage, bracing, and retail display units. The unique honeycomb structure enhances resistance to impacts, making it optimal for fragile item protection.

In commercial and industrial settings, honeycomb cardboard product applications overview reveals widespread use for pallet dividers, cushioning, and base boards. Retailers prefer honeycomb cardboard panels for point-of-sale displays and promotional stands, benefitting from both ease of customization and high-strength support.

Advanced honeycomb cardboard custom fabrication enables businesses to specify panel thickness, dimensions, and even surface graphics, ensuring solutions fit precise packaging or display needs. New applications are emerging rapidly: in construction, honeycomb cardboard panels are replacing heavier, less sustainable materials, while designers exploit them for eco-friendly furniture with eye-catching geometric forms.

Evolving innovations mean honeycomb packaging in logistics now handles challenging environments, confirming honeycomb cardboard’s position at the forefront of sustainable, versatile engineering.

Market Availability, Supplier Guidance, and Sustainability Insights

Where and how to source honeycomb cardboard sheets and suppliers

Honeycomb cardboard sheets suppliers UK can be found across the country, providing a wide range of structural honeycomb core materials for industries from packaging to retail displays. Sourcing honeycomb materials near me is streamlined by UK-based distributors and specialized fabricators, with regional availability depending on production capacity and standard stock sizes. Many suppliers accommodate bespoke requests for customized honeycomb sheet production. Before purchasing, consider the variety of honeycomb cardboard sheet thickness options, from lightweight to extra-heavy-duty, each supporting different types of load and application.

Pricing trends, availability, and regional supplier information

Honeycomb cardboard pricing trends indicate cost-effectiveness, especially compared to wood and some plastics. In the UK, honeycomb cardboard availability by region is strongest in urban and industrial centers, though rural supply can be arranged via order and delivery. Honeycomb cardboard sheets suppliers UK typically provide bulk pricing, with discounts for larger orders and recurring business. Always verify current honeycomb cardboard sheet sizes and thickness in stock to match your needs.

Environmental certifications, comparison with traditional corrugated or wood, and recycling practices

The environmental impact of honeycomb cardboard is minimal, thanks to its construction from recycled honeycomb paper and full recyclability after use. Compared to corrugated board or wood, honeycomb cardboard improvements over traditional cardboard include lower weight, fewer raw resources, and easier disposal. Many suppliers attain sustainability certifications, ensuring responsible sourcing and reprocessing. Effective recycling practices support a circular packaging economy with honeycomb products.